How to Improve Durability on a Remote Operated Vehicle (ROV)

6 min read

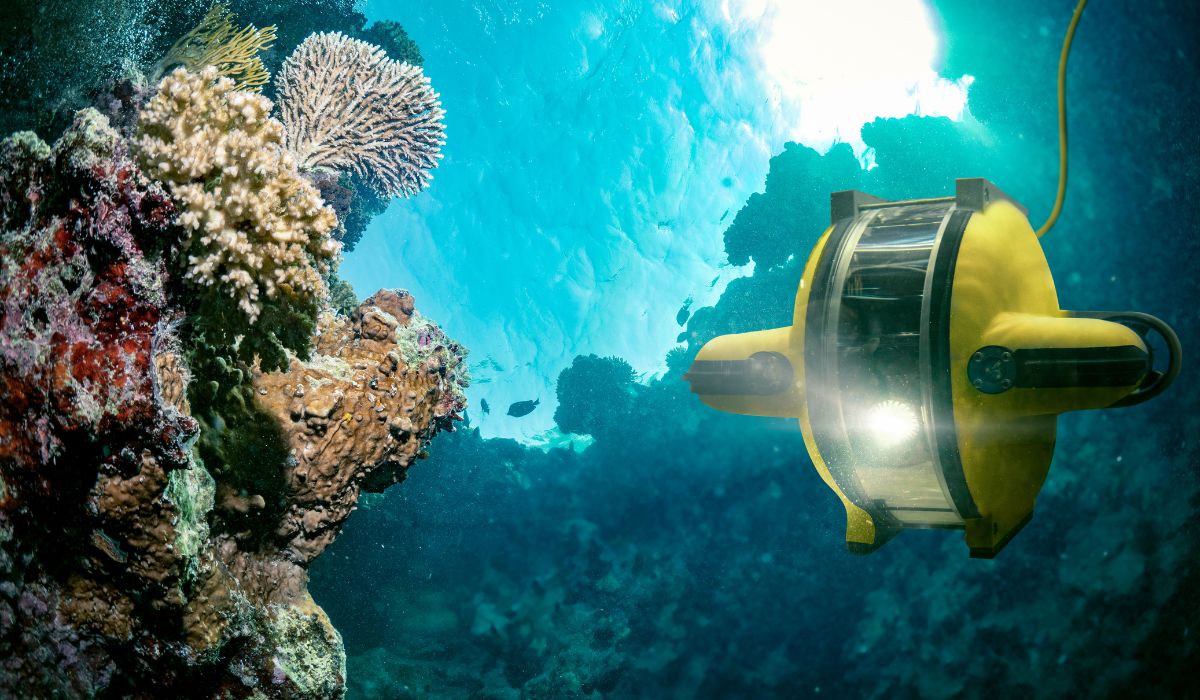

Remote Operated Vehicles (ROVs) are essential tools in industries like underwater exploration, search and rescue, and marine research.

These vehicles face harsh environments—extreme depths, high pressures, salty water, and fluctuating temperatures—making durability a top priority for users.

Enhancing ROV durability ensures that these machines can function effectively over long periods, with minimal wear and tear.

In this article, we will explore how to improve the durability of ROVs through design upgrades, advanced materials, and best maintenance practices.

Understanding ROVs and the Importance of Durability

ROVs are unmanned, remotely controlled vehicles designed for underwater use, often in places where human divers cannot go.

They are commonly used in marine exploration, underwater inspections, and salvage operations. The durability of these machines is crucial because they often operate in hostile environments—deep oceans, rough seas, or extreme temperatures.

Ensuring an ROV’s resilience not only extends its life but also enhances its efficiency and reliability in performing critical tasks.

Key Factors Affecting ROV Durability

Several factors impact an ROV’s lifespan:

1. Environmental Conditions

ROVs are primarily designed to operate in extreme underwater environments. High-pressure depths, fluctuating temperatures, and the corrosive nature of saltwater are constant challenges.

These environmental factors can cause rapid wear and tear on various components, such as motors, cables, and electronics, leading to a shortened lifespan if the vehicle isn’t equipped to withstand them.

2. Design and Build Quality

The structural integrity and materials used in the construction of the ROV are crucial for its durability.

High-quality, corrosion-resistant materials, such as stainless steel or titanium, help ensure that the vehicle can handle the harsh underwater environment.

A solid design prevents leaks, enhances stability, and reduces the risk of early mechanical breakdowns, allowing the ROV to perform reliably over time.

3. Mechanical and Electronic Stress

Mechanical stress, including constant movement and pressure changes, can cause wear on motors, propellers, and joints.

Similarly, electronic stress from fluctuating power levels, vibrations, and external temperature shifts can damage sensitive internal components.

Over time, improper stress management on both mechanical and electronic systems can lead to failures, reducing an ROV’s operational lifespan.

4. Power Supply and Battery Efficiency

A critical factor in ROV durability is the reliability of its power supply. Extended missions place a strain on batteries, making efficient power consumption essential.

Batteries like lithium-ion provide long-lasting power, while energy-efficient systems ensure that ROVs can operate for longer periods without overheating or draining the battery too quickly.

Regular monitoring and efficient power management systems can help prevent power-related failures and increase overall durability.

Upgrading Materials for Increased Durability

The materials used in the construction of an ROV significantly affect its strength and resilience. Here are some ways to improve material durability:

- High-Strength Materials: Using materials like carbon fiber or titanium for the ROV’s frame increases strength without adding unnecessary weight. These materials are resistant to corrosion and can endure high levels of stress.

- Corrosion-Resistant Materials: Since ROVs are often used in underwater environments, corrosion is a significant concern. Materials like stainless steel or specially treated aluminum help prevent rust and wear caused by saltwater exposure.

- Reinforced Hulls: The ROV’s body, or hull, is the first line of defense against external pressure. Reinforced hulls, often made from thick, durable plastics or composites, can withstand the deep-sea pressures without compromising the ROV’s functionality.

Improving Power Supply and Battery Life

An ROV’s power supply is critical for its functionality, especially during long missions. Improving power supply and energy efficiency can extend its operational time and overall durability.

- High-Capacity Batteries: Long-lasting batteries like lithium-ion or lithium-polymer are ideal for ROVs as they provide stable power output and a longer operational life.

- Energy-Efficient Components: Using energy-efficient motors, lights, and sensors helps reduce the overall power consumption, thereby conserving battery life and preventing overheating.

- Power Management Systems: Advanced power management systems can monitor and control battery usage to ensure optimal performance throughout the mission. These systems help prevent sudden power failures and enhance the reliability of the ROV.

Strengthening Waterproofing and Seals

Waterproofing is one of the most essential aspects of ROV design. If water enters the vehicle, it can cause significant damage to the internal components. Here’s how to improve sealing and waterproofing:

- Proper Sealing Techniques: High-quality seals around joints, ports, and other entry points prevent water ingress. O-rings and rubber gaskets are often used to provide a watertight seal.

- Advanced Waterproofing Materials: Seals made from high-grade rubber or silicone can withstand extreme pressure and keep internal electronics safe from water damage.

- Regular Seal Testing: Seals should be tested periodically, especially after each use. Small cracks or failures in seals can lead to bigger issues down the line.

Improving the mechanical design of an ROV can help it better withstand the forces it encounters in the field.

- Reinforced Joints: Reinforcing joints and connection points ensures that the ROV’s frame remains intact during intense operation. Using heavy-duty fasteners and bolting systems improves structural integrity.

- Shock Absorption: Shock-absorbing components, such as flexible rubber mounts, can help minimize the damage caused by impacts. These are especially useful when ROVs encounter obstacles or are deployed in turbulent waters.

- Optimized Weight Distribution: Proper weight distribution helps the ROV maintain stability and reduces stress on specific parts. Balanced weight allows for better maneuverability and control.

Advanced Maintenance Practices for Longevity

Proper maintenance is essential for any piece of machinery, and ROVs are no exception. Regular care can ensure optimal performance and durability over time.

- Cleaning: After every use, clean the ROV to remove debris, algae, and salt buildup. This prevents corrosion and ensures that the components remain free of contaminants.

- Routine Inspections: Regularly inspect the motors, sensors, propellers, and seals for any wear and tear. Catching small issues early can prevent larger failures.

- Component Servicing: Over time, motors and propellers may need servicing or replacement. Keeping these components in top condition will help the ROV perform better and last longer.

Thermal Management for Electronics

Heat buildup can damage internal electronics, especially during long missions. Proper thermal management is key to ensuring durability.

- Cooling Systems: Installing cooling fans or liquid cooling systems can help prevent overheating of electronic components.

- Heat Dissipation Materials: Using materials like heat sinks or conductive coatings can help manage heat better and distribute it away from sensitive parts.

- Thermal Insulation: Insulating internal compartments ensures that extreme external temperatures do not affect internal electronics.

Innovative Technologies to Improve ROV Durability

Technological advancements are continually improving ROVs’ durability:

- AI and Autonomous Systems: AI-driven systems can help identify issues with the ROV’s performance in real-time. These systems can detect wear and adjust operations to prevent further damage.

- Self-Repair Technology: Some modern ROVs are designed to automatically detect and repair minor issues, which can help extend their lifespan.

Testing and Evaluating ROV Durability

It is important to regularly test the ROV under various conditions to assess its durability.

- Stress Testing: Simulating extreme environmental conditions (e.g., deep-sea pressure or harsh temperatures) can help determine an ROV’s ability to handle real-world scenarios.

- Metrics for Durability: Tracking the performance of ROV components (e.g., battery life, propeller efficiency, sensor accuracy) helps measure overall durability and effectiveness.

Cost vs. Durability: Finding the Right Balance

While it’s essential to invest in high-quality materials and technology for durability, cost is always a consideration. Finding the right balance between durable features and budget is critical.

- Smart Investment: Choose upgrades that offer the most significant durability improvements for the least cost. Sometimes, focusing on specific areas like seals or batteries can offer the most return on investment.

- Long-Term Value: Investing in durable components may have a higher upfront cost but can save money in the long run by reducing maintenance and repair needs.

Conclusion: Future of Durable ROVs

The future of Remote Operated Vehicles lies in their increasing durability and efficiency. As technology advances, ROVs will become more resilient to environmental stress, ensuring better performance for underwater research, industrial applications, and exploration. By focusing on better materials, smart power systems, and robust design, industries can rely on ROVs for longer missions and in more extreme conditions.

Whether you’re deploying ROVs in deep waters or using them for inspection work, improving their durability will ensure reliable, long-term operation.